Championing Innovation & Sustainability

Since 1949, Artistic Milliners has continuously evolved over the years into a global powerhouse of denim, apparel, design & finishing, and even clean energy. At the heart of all the ambition and success, though, is the day-to-day pursuit of creativity, excellence, and sustainability.

From its recent sustainability report published by Rivet, Artistic Milliners shares its significant progress in meeting its net-zero emissions across the board by 2040, including renewable energy production, traceability, waste reduction, organic cotton farming, regenerative agriculture, and championing fair labor practices.

Its partnership with Vizoo, the industry’s leading material digitization company, is another integral piece that furthers its innovation and sustainability agenda.

“As industry contributors, we bear the responsibility to drive positive transformations for our planet and its people.“- Yaqoob Ahmed, Artistic Milliners chairman

Leveraging 3D and Material Digitization Technology When Building Sustainable Processes

As one of the world’s top denim manufacturers, Artistic Milliners recognized the importance of 3D technologies to meet its goal of lessening industrial waste and staying at the forefront of the textile industry’s digital transformation.

At the material level, it became evident that choosing the right scanning technology partner would play a pivotal role in its digital transformation journey.

Dissatisfied with its material scanning process, the company found that Vizoo xTex technology was a common solution used by many other textile manufacturers. With their strong focus on efficiency and automation, Artistic Milliners was very clear about the requirements for its optimal material scanning system.

“We wanted a smooth automated workflow that would give us accurate results that are true to life and photorealistic. And, of course, we didn’t want to see any obvious repeating texture features in our digital materials. We needed seamless, natural tiling. Vizoo’s xTex technology demonstrated lightning-fast capture speeds, impeccable output quality, and the first-hand experience of other clients already benefiting from Vizoo technologies were the reasons for our final decision. As a result, we have successfully implemented Vizoo’s material digitization solution at our Pakistani headquarters in 2022.”

-Amber Isaac, DPC lead at Artistic Milliners and Star Fades International

Empowering Clients by Increasing 3D Asset Quality and Sample Production Speed

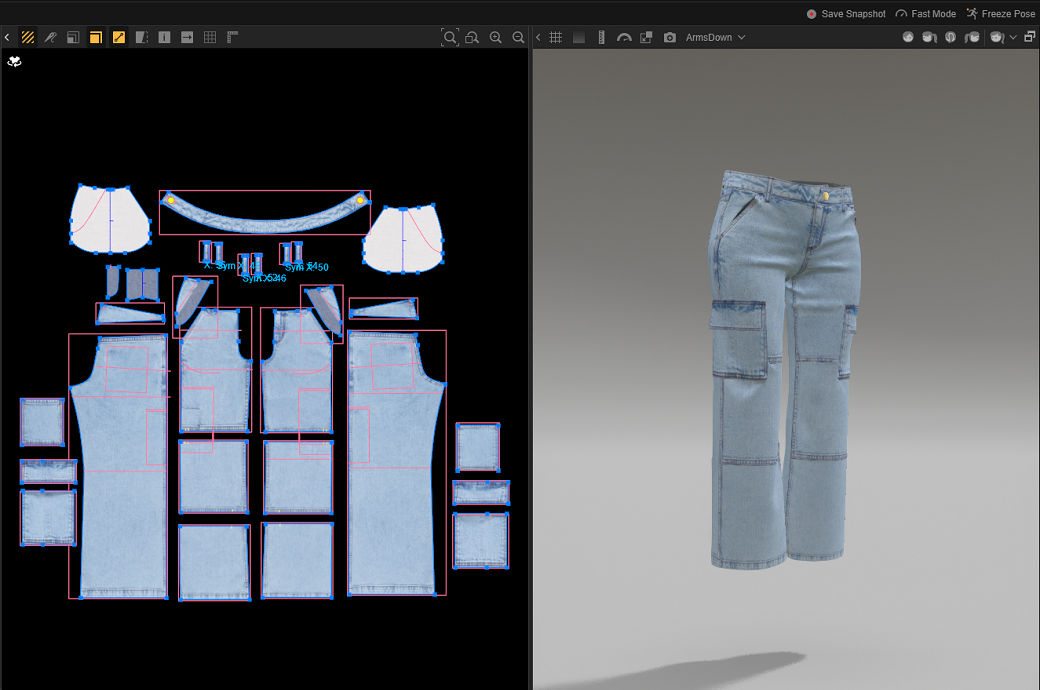

Artistic Milliners leverages the xTex A4 scanner for visual properties and physX Platform for fabric drape properties. This combination of Vizoo solutions is instrumental in creating highly accurate digital twins, enabling life-like garment simulations for digital product creation workflows.

Since implementation, the company has significantly accelerated their texture creation processes, enabling them to deliver superior-quality 3D assets to their clients in record time.

Andrew Bougie, client success manager for the Americas at Vizoo, said: “When working with Artistic Milliners, we found the core objective of their material digitization initiative was to provide their brand clients with exact digital representations of their textiles. Also, these digital materials needed to seamlessly integrate into their clients’ digital product development workflows to facilitate collaboration, reduce lead times, and minimize waste through reduced physical sampling.”

Efficient Digitization Workflow with Interoperable Fabric Data

Not all brand clients use the same 3D CAD simulation program. Thus, Artistic Milliners implemented a digitization workflow that allows for the output of interoperable digital fabrics. Amber and the DPC team at Artistic Milliners went above and beyond to share step-by-step information about their workflow, providing valuable behind-the-scenes insight into their day-to-day processes.

Step 1: Capture Visual Properties

In the Toolbox: xTex A4 Scanner

Vizoo’s xTex technology is a combination of the xTex A4 scanner hardware and xTex software, which is used for capturing and tiling textures.

Artistic Milliners defined a standard square 30×30 cm sample size for the scanning process to capture the color, reflectivity, surface structure, transparency, and any metallic properties.

After scanning and creating a seamless repeat, they use the xTex software to export in the U3M file format with standard texture maps such as Base Color, Normal, Displacement, Metalness, Roughness, and Transparency.

Step 2: Measure Physical Properties

In the Toolbox: Vizoo Cantilever

Artistic Milliners provides digital materials in multiple formats so they can be used for fabric drape simulation in a variety of apparel CAD software solutions.

To accommodate this flexibility and create interoperable material files, they take some initial measurements with the Vizoo cantilever device to use later in the physX Conversion tool process.

The specific measurements required are overhang length, contact distance, and moving distance from each of the 25×5 cm Warp, Weft, and Bias strips cut from the 30×30 cm sample.

In the Toolbox: BrowZwear FAB

Continuing with physical properties, they use the same 25×5 cm fabric strips in the BrowZwear FAB device.

This tool automates the measurement of a fabric’s physical parameters, such as mass, friction, thickness, bend, stretch, and shear strength.

The native output from the FAB is meant for BrowZwear’s apparel CAD software, VStitcher, so the next step in the process is to enable interoperability with other software.

Step 3: Convert for CLO

In the Toolbox: physX Conversion Tool

With the physical property measurements as input, Artistic Milliners uses the new physX Conversion tool to enable CLO compatibility.

Using the physX Conversion tool greatly reduces the time required to measure physical properties. Additionally, removing most of the manual measurement steps from the standard CLO measurement process reduces errors and increases measurement consistency.

Step 4: Finalize Digital Materials

In the Toolbox: BrowZwear and CLO

The visual and physical properties are combined as U3MA files in the xTex Software. This means they can be imported directly into VStitcher and are immediately ready for drape simulation.

For CLO, the visual and physical properties are combined into a single zfab after both are imported into CLO.

Step 5: Validate Accuracy

In the Toolbox: Vizoo Drape Reference

Artistic Milliners’ last step is validation, which is essential to ensure they provide accurate digital materials to their clients.

The validation process uses Vizoo’s drape reference geometry to compare digital simulation results with physical reference photos. The tool comes with a digital counterpart for validation in VStitcher and CLO.

Once validated, they can share the materials with clients to use in their DPC workflow or experiment internally with digital variants and samples before producing physical versions.

Amber concludes: “The physX conversion tool is the missing link between interoperability of physical properties. By using this workflow, the company saves 40% of their time compared to doing separate BrowZwear and CLO3D measurements. In my role as DPC Lead for Artistic Milliners and Star Fades International, I have seen an immediate benefit by saving time and achieving consistent results in the measurement process.”

Partner in Innovation and Sustainability

By adopting Vizoo’s cutting-edge material digitization technology, Artistic Milliners has once again positioned itself as a leader in the digital transformation of the textile industry and underscored its commitment to sustainability and reducing its ecological footprint.

Fibre2Fashion News Desk (HU)